| Pages:

1

2

3 |

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

My buggy build (Zephyr I)

I am addicted ..... New build.

This will be the first buggy that I build The Zephyr I.

I am hoping to get feed back, tips and hints. Thanks for reading.

This is all the steel and wheels for the rolling chassis.

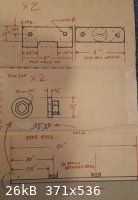

Actual size lay out for the goose neck.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

eric67m

Senior Member

Posts: 543

Registered: 11-9-2015

Location: Monroe, Washington

Member Is Offline

|

|

Right on. I look forward to watching your progress.

Flying A mixed quiver of Flysurfer Peak kites.

Rollin in the Popeye The Welder Playa buggy.

|

|

|

jantie

Senior Member

Posts: 644

Registered: 6-12-2006

Location: Rotterdam NL

Member Is Offline

Mood: wind please!!

|

|

Nice.

What kind of rims are these?

And are those bigfoot midi tyres?

The distance between front axle and fork pipe is

for me a little short. I would at least double or even triple the distance you have now to make it less nervous at high speed.

Keep posting :D

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

The rims are 8in x 7in 52mm hub 52mm x 20mm bearings.

Tyres are 18in x 9.5in x 8in 4 ply. (midi XL)

If increasing the distance between the axle and fork, do you need to change the head angle to be more in line with the axle? (more caster, more caster

is more stable)

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

jantie

Senior Member

Posts: 644

Registered: 6-12-2006

Location: Rotterdam NL

Member Is Offline

Mood: wind please!!

|

|

Quote: Originally posted by Jack.Oh  | The rims are 8in x 7in 52mm hub 52mm x 20mm bearings.

Tyres are 18in x 9.5in x 8in 4 ply. (midi XL)

If increasing the distance between the axle and fork, do you need to change the head angle

to be more in line with the axle? (more caster, more caster is more stable) |

yes true, but too much can shake/shimmy the tire and rememder: there is only 1 frontwheel on your bug, it's not a car.( or a Crab..  )

i've just measured mine and i have it neutral. (give or take 0.1 degrees due to tire-pressure)

so riding backwards is also stable.. :D

i've driven so many time's well over 50Mph and backwards not that much slower and the stability with neutral caster is great.

even with the side-ride wich adds an easy 100kg with passenger (with or without kite) has no negative influence of the stability.

also with the tandem (speed +50Mph) wich increases the downforce on the rear-axle dramaticly, i only need to deflate the front tire slightlty to go

like it's a solo-run.

but that's how is see it, it is your project.

perhaps a trialrun with neutral and then positive caster will make it easier to choose..

keep them pics coming.

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Quote: Originally posted by jantie  | Quote: Originally posted by Jack.Oh  | The rims are 8in x 7in 52mm hub 52mm x 20mm bearings.

Tyres are 18in x 9.5in x 8in 4 ply. (midi XL)

If increasing the distance between the axle and fork, do you need to change the head angle

to be more in line with the axle? (more caster, more caster is more stable) |

yes true, but too much can shake/shimmy the tire and rememder: there is only 1 frontwheel on your bug, it's not a car.( or a Crab..  ) )

i've just measured mine and i have it neutral. (give or take 0.1 degrees due to tire-pressure)

so riding backwards is also stable.. :D

i've driven so many time's well over 50Mph and backwards not that much slower and the stability with neutral caster is great.

even with the side-ride wich adds an easy 100kg with passenger (with or without kite) has no negative influence of the stability.

also with the tandem (speed +50Mph) wich increases the downforce on the rear-axle dramaticly, i only need to deflate the front tire slightlty to go

like it's a solo-run.

but that's how is see it, it is your project.

perhaps a trialrun with neutral and then positive caster will make it easier to choose..

keep them pics coming.

|

So, yesterday it was too cold to work in the garage. Instead did some reading about the geometry on front of a buggy. First off I

think I used the wrong term, I am speaking of rake and trail. PTW site has a page on explaning the rake and trail on a buggy.

It looks like 25 - 28 degrees rake and 80mm - 100mm trail seems standard.

I will check the geometry of the several fork designs I have in mind.

May need to change the goose neck. At the moment the rake is at 28 degrees.

Stay tuned.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Ok, the tepm was in the 40s today and I had some time to mess around in the garage.

Worked on getting some Ideas down for the back axle.

Also, I bent the side rails.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Does anyone have any suggestions for the distance from the ground to the bottom of the goose neck? What is it on and MG or an Apex?

Thanks

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

kteguru

Senior Member

Posts: 807

Registered: 15-3-2009

Member Is Offline

|

|

Shaping up really nice. Can't wait to see it in fall.

Two thumbs up   |

|

|

jantie

Senior Member

Posts: 644

Registered: 6-12-2006

Location: Rotterdam NL

Member Is Offline

Mood: wind please!!

|

|

Quote: Originally posted by Jack.Oh  | Does anyone have any suggestions for the distance from the ground to the bottom of the goose neck? What is it on and MG or an Apex?

Thanks |

The last part of the gooseneck wich is horizontal is

about 5 inch in height on my homebrew buggy. But need to say that I use bigfoot fullsize

inflated to 0.2 bar so it drops a bit due to bodyweight.

Not all goosenecks are horizontal like for example the Libre V-Max that I used as a baseline for the Crab.

I'm very curious to know what kinda seat your gonna use or fabricate because of the form me the little odd shape of the sidebars.

The one I mostly use is a Libre full Race seat and would never fit on your buggy.

For the rear axle M20 and the sidebars M16 i used this instead of a short and regular bold:

Keep posting

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Thanks Dean, there is a lot more to figure out. I hope to have it done by then.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Quote: Originally posted by jantie  | Quote: Originally posted by Jack.Oh  | Does anyone have any suggestions for the distance from the ground to the bottom of the goose neck? What is it on and MG or an Apex?

Thanks |

The last part of the gooseneck wich is horizontal is

about 5 inch in height on my homebrew buggy. But need to say that I use bigfoot fullsize

inflated to 0.2 bar so it drops a bit due to bodyweight.

Not all goosenecks are horizontal like for example the Libre V-Max that I used as a baseline for the Crab.

I'm very curious to know what kinda seat your gonna use or fabricate because of the form me the little odd shape of the sidebars.

The one I mostly use is a Libre full Race seat and would never fit on your buggy.

For the rear axle M20 and the sidebars M16 i used this instead of a short and regular bold:

Keep posting

|

Thanks for the info, I was looking at 4 inches but that seemed too low. 5 sounds better.

The side rails will have a few more bends, plus they are not trimmed to length yet. But I was so excited, I had to kinda size them up.

I like the stand off for the axle, I will have to find some. Some metric hardware is hard to find in the US.

The seat I will be making myself. Plus, there will be a backrest.

Lots of ideas, I may have to change somethings...???

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

rtz

Posting Freak

Posts: 1107

Registered: 12-10-2010

Location: Edmond, OK

Member Is Offline

|

|

You can get 3/4" ones easily, then swap out your bearings; or have a slightly loose fit in the bearing to bolt connection.

Sting 1.7, 2.4 - Flow 2, 3, 4, 5 - Reactor 2.2, 2.8, 3.5, 4.4, 5.5 - Yakuza 2.2, 2.7 - JOJO 9

|

|

|

rtz

Posting Freak

Posts: 1107

Registered: 12-10-2010

Location: Edmond, OK

Member Is Offline

|

|

You could build a low rider; just depends on the terrain you ride on and how much ground clearance you need.

4", 5", 6"? I'd get the seat and side rails figured out then use the gooseneck to connect to the front fork.

As far as rake/trail; my experience: something like an older peter Lynn; with the fork nearly straight up and down. Very, very easy to turn with the

legs and good for doing spin tricks. Makes the buggy feel extremely nimble.

With a lot of rake; you need to be careful of flop. The tire will feel like it wants to flop over to one side or the other. But I haven't noticed it

to be an issue. Just something to think about and consider.

I don't think the head tube angle is super end all be all critical. Between straight up and down and not too far raked back and you will be fine.

This likely won't be the last buggy you ever build. Just the first of many.

Sting 1.7, 2.4 - Flow 2, 3, 4, 5 - Reactor 2.2, 2.8, 3.5, 4.4, 5.5 - Yakuza 2.2, 2.7 - JOJO 9

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Quote: Originally posted by rtz  | | You can get 3/4" ones easily, then swap out your bearings; or have a slightly loose fit in the bearing to bolt connection. |

I found some today McMaster Carr a little pricey...

I really would like to stay with the common hardware you would find in the industry. I did consider going the 3/4 inch rout.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

ColinW

Member

Posts: 243

Registered: 12-4-2015

Location: Victoria BC

Member Is Offline

|

|

I am following this with great interest!

Thanks for taking the time to post the progress in such depth.

|

|

|

jantie

Senior Member

Posts: 644

Registered: 6-12-2006

Location: Rotterdam NL

Member Is Offline

Mood: wind please!!

|

|

Quote: Originally posted by Jack.Oh  | Quote: Originally posted by rtz  | | You can get 3/4" ones easily, then swap out your bearings; or have a slightly loose fit in the bearing to bolt connection. |

I found some today McMaster Carr a little pricey...

I really would like to stay with the common hardware you would find in the industry. I did consider going the 3/4 inch rout. |

a little pricey..??? that is what we call stealing..

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Quote: Originally posted by ColinW  | I am following this with great interest!

Thanks for taking the time to post the progress in such depth. |

Thanks, I will post as progress is made. Also any corrections or discoveries.

Are you considering building also.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Ok, some more components finished..

First some axle parts...

I the was planing on finishing the axle.

But the 17.5mm drill I had did not drill mild steel.

I ordered a new one, but it will be middle of this week before it arrives.

So I made the goose neck...

Thanks for looking.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

rtz

Posting Freak

Posts: 1107

Registered: 12-10-2010

Location: Edmond, OK

Member Is Offline

|

|

High quality build!

Sting 1.7, 2.4 - Flow 2, 3, 4, 5 - Reactor 2.2, 2.8, 3.5, 4.4, 5.5 - Yakuza 2.2, 2.7 - JOJO 9

|

|

|

jantie

Senior Member

Posts: 644

Registered: 6-12-2006

Location: Rotterdam NL

Member Is Offline

Mood: wind please!!

|

|

Nice..!!!!

those steel rims are so cool.

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Yesterday the new drill that I ordered showed up.

I was able to finish the end caps for the back axle.

I will probably finish the back axle this weekend.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

ColinW

Member

Posts: 243

Registered: 12-4-2015

Location: Victoria BC

Member Is Offline

|

|

Quote: Originally posted by Jack.Oh  | Quote: Originally posted by ColinW  | I am following this with great interest!

Thanks for taking the time to post the progress in such depth. |

Thanks, I will post as progress is made. Also any corrections or discoveries.

Are you considering building also. |

I have a bunch of buggy parts that mostly fit together... The existing fork is too short for the disc wheels I want to use so I got some plates made

up to extend them. I wasn't at all sure about the angles and trail and rake, so made the plates BIG and put many holes in them. The goose neck will

have to be extended and re angled as well. I also need to reinforce the side rails (not nearly stiff enough).

I am a carpenter and don't know how to weld but I've finally got the equiptment set up to try. I haven't been able to find any local welding courses

that aren't full time trades courses. I have met a great guy who does lots of shiny stuff for the local yachting market, but I don't want to take

advantage of him, AND I want to do this myself.

|

|

|

tomdiving

Member

Posts: 416

Registered: 4-3-2017

Member Is Offline

Mood: thankful for this site

|

|

colin

welding isn't difficult, BUT, do you want to potentially risk your life on something that may or may not be done correctly while you try to learn a

new craft?

tom

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Yes, welding is definitely a practiced skill. And I am no expert. As my son Kyle (Dredbro here) said to me the other day after seeing my welds, "A

grinder and paint make you the welder you ain't!"... His welding skill is way better than mine. I usually take some scrap pieces of the same material

that I am working with and make some test welds to adjust all my settings. I only MIG weld at this point, and only mild steel.. I have never welded

stainless.

Colin, I am with you on wanting to do the work your self. As some one on this forum posted at some time.. some thing like " there is no feeling better

that rolling down the beach in a buggy you made your self."

Tom your point is very valid also. You need to be sure of your own skills. You are risking life and limb every time you put a kite up. So be sure of

your equipment and your skill level.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

ColinW

Member

Posts: 243

Registered: 12-4-2015

Location: Victoria BC

Member Is Offline

|

|

Quote: Originally posted by tomdiving  | welding isn't difficult, BUT, do you want to potentially risk your life on something that may or may not be done correctly while you try to learn a

new craft?

tom |

Point taken. I was more concerned with setting fire to the house or myself. This is why I am not sure the University of Youtube will suffice. Looks so

easy tho.

Also not really willing to admit that this is out of my reach  So I'm

going down to the garage to round up all the flamables out of the way.

|

|

|

rtz

Posting Freak

Posts: 1107

Registered: 12-10-2010

Location: Edmond, OK

Member Is Offline

|

|

I suggest everyone pick up a welder and learn how to use it. Acquire a bunch of scrap metal. Chop it up into smaller pieces. Set the machine settings

for the thickness being welded. Get some half way decent welds. Now try it with the machine set to high and too low so you know what that's like.

When the machine is dialed in; cut some of your welds in half so you can see what the weld penetration looks like.

Take 2 pieces that have been welded together and put them in a vise and beat the end over with a hammer to see how strong the weld is.

Mig, Tig, stick. Take up the one that appeals to you.

Sting 1.7, 2.4 - Flow 2, 3, 4, 5 - Reactor 2.2, 2.8, 3.5, 4.4, 5.5 - Yakuza 2.2, 2.7 - JOJO 9

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Got the rear axle done.

Now I know, some might be like ..... Hey that seat Rocks!!!

But, the seat is not staying.....

This week I will work on getting the side rails finished up.

Still trying to figure out how to hold everything together / alignment for welding.

And I need to get the rest of the hardware...

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Quote: Originally posted by rtz  | I suggest everyone pick up a welder and learn how to use it. Acquire a bunch of scrap metal. Chop it up into smaller pieces. Set the machine settings

for the thickness being welded. Get some half way decent welds. Now try it with the machine set to high and too low so you know what that's like.

When the machine is dialed in; cut some of your welds in half so you can see what the weld penetration looks like.

Take 2 pieces that have been welded together and put them in a vise and beat the end over with a hammer to see how strong the weld is.

Mig, Tig, stick. Take up the one that appeals to you.

|

That's a great way to learn. I actually think we did a very similar thing 30 years ago when I took welding in school.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

Jack.Oh

Member

Posts: 184

Registered: 12-4-2019

Location: Aurora, Oh

Member Is Offline

|

|

Ok, moving along.... Yesterday I started the side rails.

I think the shape is Ok, have not made any other bends.

I don't have any actual size drawings. Here is what I did so far.

Then I lined them up and trimmed both ends. Still need to even them up.

I drew the width of the goose neck plus the plates and then the inside of the rails width, to get my trim angles close.

US417

Custom buggy "Zephyr II"

Pansh A15 9m, 12m, 15m

Pansh Genesis 4m, 6m

|

|

|

| Pages:

1

2

3 |