| Pages:

1

2

3

4 |

rtz

Posts: 1106

Registered: 10-12-2010

Location: Edmond, OK

Member Is Offline

|

|

6204 is the bearing for the PL wheels. 6204's with a 3/4" ID are listed on eBay vs's the standard 20mm ones if you want to use a 3/4" bolt or stud

for your axles:

http://www.ebay.com/itm/6204-2RS-12-6204-2RS-3-4-1-PC-FACTOR...

Have you considered welding a 3/4" nut into your axle tube? Popeye has a video on building the axle where he welds the nut onto a round disc to

center it and welds that into the axle tube.

Show me a close up of the center of a metal wheel that you were looking to use and what type of bearing setup it uses.

Sting 1.7, 2.4 - Flow 2, 3, 4, 5 - Reactor 2.2, 2.8, 3.5, 4.4, 5.5 - Yakuza 2.2, 2.7 - JOJO 9

|

|

|

OffAxis

Posts: 202

Registered: 2-23-2016

Location: Central PA

Member Is Offline

|

|

I was thinking of using these wheelbarrow rims. But might purchase the PL plastic rims because the price is very similar.

These are the bearings that are compatible with the wheelbarrow rims:

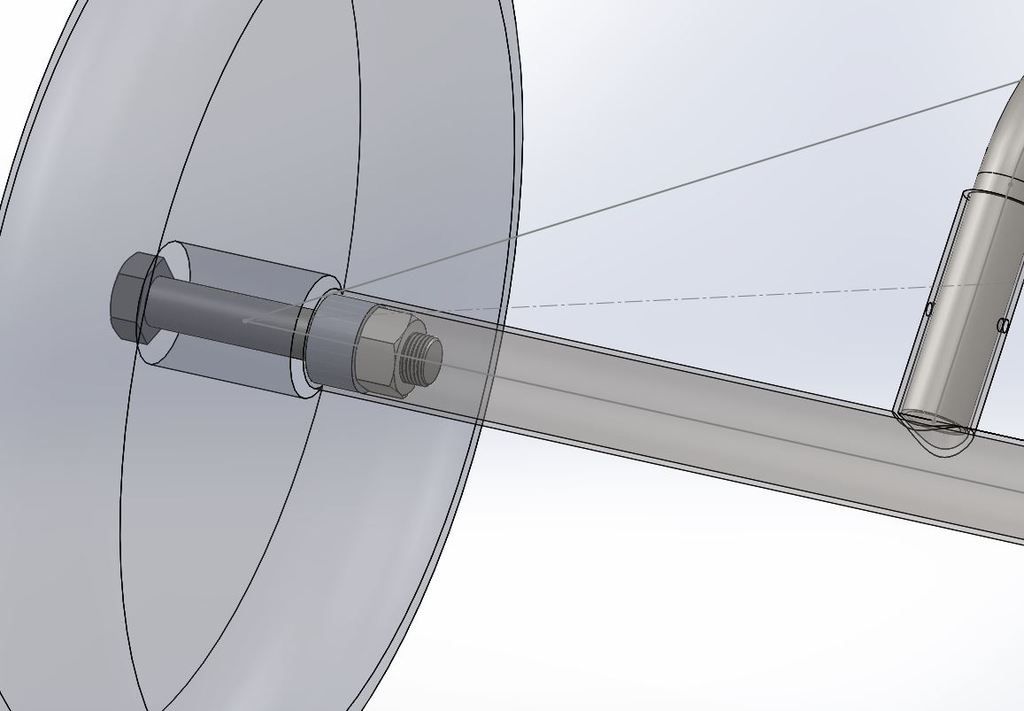

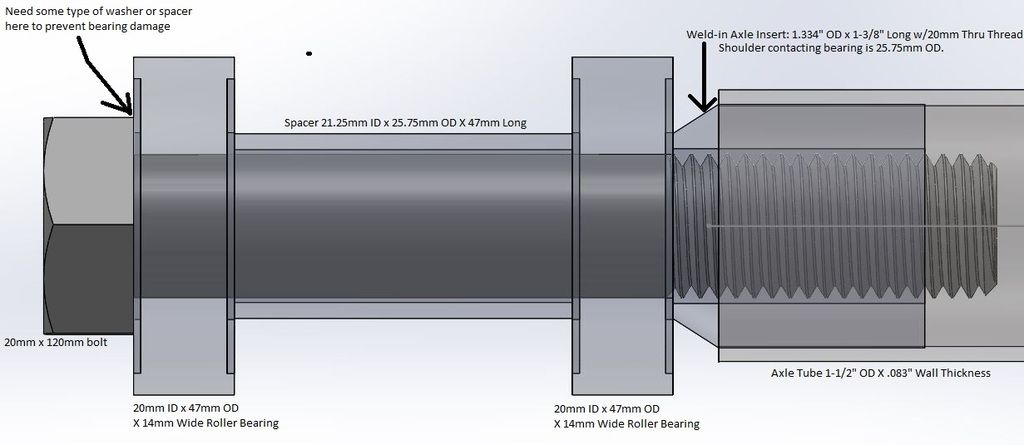

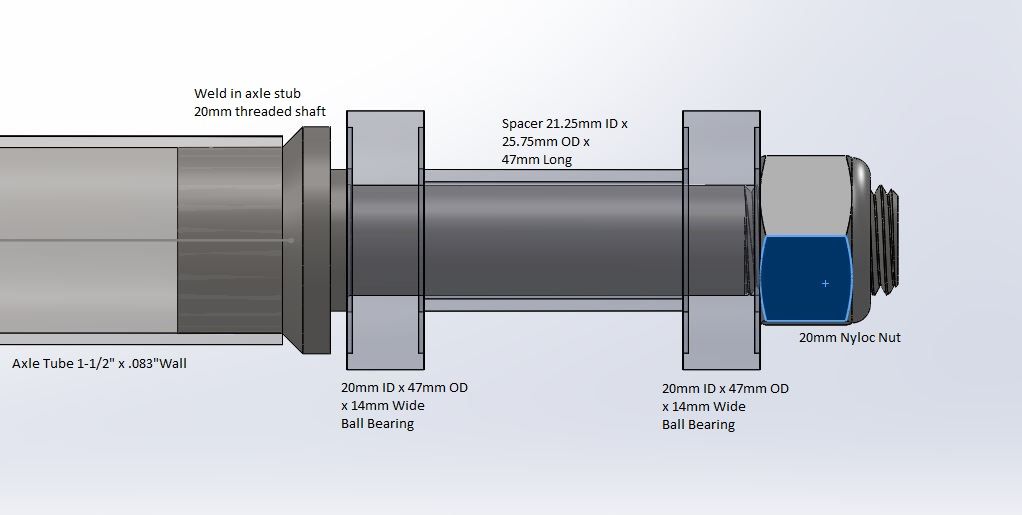

I have watched the popeye video and plan on doing the same. It will look something like this:

|

|

|

WELDNGOD

Posts: 5143

Registered: 10-11-2006

Member Is Offline

Mood: Dyin' to go flyin'

|

|

Been there done that... The weld will crack. Get the PL wheels.

WELDNGOD on VIMEO

https://vimeo.com/user2580342

NAPKA US187

PKD

Combat 2.4 / 4.2

Century 1.8 / 5.5

Century II 2.2/2.8/3.5/4.5 /10.0

Brooza IV 3.0 prototype

Buster Soulfly 1.5 / 2.2 (KIA)/ 3.3 (lost at sea)

Buster Soulfly PRO 3.3 / 4.4

Buster (gen 1) 5.5

FLEXIFOIL

Sting 1.7 Punk

Rage 2.5 / 3.5/ 4.7

Revolution 1.5 SLE

17 ply Custom TRAMPA w/ verTIGo trucks

2 homebrew buggies,2 homebrew KYTBYKS,1 homebrew tandem trailer

GOPRO 3 WHITE, 3+ BLACK, HERO5 BLACK

CONTOUR HD

LET YOUR SOULFLY!

RIDER for KOKOPELLI KITER

|

|

|

Chook

Posts: 141

Registered: 10-25-2009

Location: Esperance Western Australia

Member Is Offline

Mood: I work at home from 8.00am to 12 knots

|

|

Don't use steel if you can avoid them. They rust around the valve and trap moisture between the halves. As soon as they chip they look like crap. Salt

yellows the paint on the rims too.

I just replaced these sort of rims on a "Pelican" yacht jinker. They we not 12 months old. The bearings in them were complete crap too. The rubber

seal didn't even run in a groove on the inner race.

I haven't bent an 3/4" axle (but use Hitensile bolts) but have changed all my 11 landyachts and 3 buggies over to 20mm to keep them all standard. I

only have 2 sizes of bearings and use high quality Stainless steel bearings.

Modified Sysmic S2 Buggys

7m R1

8m R1 2

11m R1

15m R1

15m Chrono 2

18m Chrono

18m ELF

|

|

|

John Holgate

Posts: 1512

Registered: 6-9-2009

Location: Australia

Member Is Offline

Mood: Cruising...

|

|

Eventually, you might want a nice set of alloy Sysmic rims - so go with the 20mm. I used some threaded gal rod on this one... http://www.extremekites.com.au/gallery/image/132-vermin-stub... Rather than use a bolt, I have also inserted some 20mm rod into my Vmax axle and

locked it in place with a nut....then I slide the tire onto the threaded rod and put a nylock on the outside. This has been easy to take on and off

and doesn't come loose.

|

|

|

OffAxis

Posts: 202

Registered: 2-23-2016

Location: Central PA

Member Is Offline

|

|

John, why don't the treads get damaged from the bearings. I don't think i'm going to design a rolling element to be supported by bolt threads.

Does anyone know of a source of M20 bolts in the USA other then McMasterCarr? Or an internet store that ships to the US. I can't find anything and

until I do I think I'm gonna stick with 3/4" or 5/8".

|

|

|

WELDNGOD

Posts: 5143

Registered: 10-11-2006

Member Is Offline

Mood: Dyin' to go flyin'

|

|

Grainger or McMaster-Carr

WELDNGOD on VIMEO

https://vimeo.com/user2580342

NAPKA US187

PKD

Combat 2.4 / 4.2

Century 1.8 / 5.5

Century II 2.2/2.8/3.5/4.5 /10.0

Brooza IV 3.0 prototype

Buster Soulfly 1.5 / 2.2 (KIA)/ 3.3 (lost at sea)

Buster Soulfly PRO 3.3 / 4.4

Buster (gen 1) 5.5

FLEXIFOIL

Sting 1.7 Punk

Rage 2.5 / 3.5/ 4.7

Revolution 1.5 SLE

17 ply Custom TRAMPA w/ verTIGo trucks

2 homebrew buggies,2 homebrew KYTBYKS,1 homebrew tandem trailer

GOPRO 3 WHITE, 3+ BLACK, HERO5 BLACK

CONTOUR HD

LET YOUR SOULFLY!

RIDER for KOKOPELLI KITER

|

|

|

ssayre

Posts: 3587

Registered: 8-15-2013

Location: Indiana

Member Is Offline

|

|

do you still the angle of the fork? I could check mine for you if you still need that

|

|

|

Bladerunner

Posts: 9679

Registered: 10-17-2006

Location: Vancouver

Member Is Offline

|

|

People have tried to reinvent the wheelbarrow wheel from times before actual buggy wheels were available CHEAP!

There are all sorts of reasons the wheelbarrow wheels don't work in the long haul.

You are throwing good money at a bad idea IMHO. Go with cheap PL plastic wheels and 20mm bolts. NOT doing so will not allow you to easily change out

to better buggy wheels down the road.

I thought your side goal was to build so others can buy your stuff? Going imperial won't be of much value to others?

Kites: 2.5m Profoil , Quadrifoil XL kitesurfer, NPW 5 Danger.

Flexifoil: 1.7m Sting, 4.9m Blade 3, 9m Blade 2.

Flysurfer : 19m Speed 2 SA, 7m Pulse

Peter Lynn :18m Phantom, 15m Synergy, 10m Synergy, 1200 Farc, 460 Sarc, 130 Tarc, 5m Peel, 4.2m , 6.4, 8.5 C-Quads, 3.5 LS2 single skin.

Rides: Flexi / P.L. Frankin'Buggy , Shaped + straight skiis, sand skis, Coyote blades. Core 95 ATB. RKB R2 ATB .

Ken (K2)

|

|

|

John Holgate

Posts: 1512

Registered: 6-9-2009

Location: Australia

Member Is Offline

Mood: Cruising...

|

|

| Quote: |

John, why don't the treads get damaged from the bearings. I don't think i'm going to design a rolling element to be supported by bolt threads.

|

It doesn't spin against the threads, in fact its the bit of the bearing the nut comes up against and locks the wheel in place. I've done a few

thousand km's on this setup so far on both buggies and the threads are still fine and it's easy to cut a new bit to length if I need to. Beamer Bob

put me onto it a few years ago. Easy to source locally too rather than try and get 20mm SS bolts.

|

|

|

OffAxis

Posts: 202

Registered: 2-23-2016

Location: Central PA

Member Is Offline

|

|

Bladerunner: I would agree. Not going with 20mm does make things more challenging when it comes to choosing wheels. But with a simple bearing change

out to 47x3/4"x14mm I think all the problems go away. So its not the end of the world. Once i begin looking into what spacers are readily available it

might make the decision easier. The reason I lean towards imperial hardware is because it is way easier to get then metric.

John: You are correct, it does work. The decision to make sub shafts like that is probably because it was a cheap solution. But I'm of the opinion

that it is a poor design choice to have bearings supported by threads. The threads and bearing can become damaged easily if things loosen up. To me,

I believe it is worth the slight additional cost to avoid this scenario.

ssayre: I would be interested in knowing what a common fork angle is.

|

|

|

BeamerBob

Posts: 8308

Registered: 5-11-2007

Location: Down on the bayou

Member Is Offline

|

|

I got the threaded rod stub axle idea from Popeye. I got tired of having to buy expensive bolts every time I tried a different wheel configuration.

They are infinitely adjustable. There is no need to worry about the threads being damaged by the large surface area of the bearing races. I too have

several thousand miles on this setup and I've never had even a scuff on the threads. Another thing about using stub axles, is it gives the ability to

lock the axle into the buggy with the jam nut and then the outside locknut allows perfect tightness on the wheel bearings without worrying about

anything coming loose. You might have to struggle to get bolts with the right shoulder length for your wheels if you are locked into that path.

Coastal Wind Sports Team Rider

Landsegler Disc wheels

PTW Hero Buggy - XXtreme ApeXX Buggy US 88 - Libre Hardcore

IvanpahBuggyExpo.com

Youtube link

Bob Muse

HQ Montana X 8m, Montana IX 12m, HQ Ignition LEI 5m,

PL Phantom 12m, 15m, Big Blu 24m+, Synergy 10m, Venom 10m, 13m , Phantom II 12m Vapors 3.8, 5.4, Crosskite Sonic 7m, PKD Combat 10.3m

Uturn Butane 2.5m PKD Buster 3m Genetrix Hydra 7m Ozone Yakuza GT 14m

|

|

|

WELDNGOD

Posts: 5143

Registered: 10-11-2006

Member Is Offline

Mood: Dyin' to go flyin'

|

|

There is always 20mm round bar ,then weld a short 3/8 bolt on the end and use a locknut and washer to keep the wheel on. That is my current setup .

Works great! Not cheap though.... http://www.onlinemetals.com/merchant.cfm?pid=22286&step=...

WELDNGOD on VIMEO

https://vimeo.com/user2580342

NAPKA US187

PKD

Combat 2.4 / 4.2

Century 1.8 / 5.5

Century II 2.2/2.8/3.5/4.5 /10.0

Brooza IV 3.0 prototype

Buster Soulfly 1.5 / 2.2 (KIA)/ 3.3 (lost at sea)

Buster Soulfly PRO 3.3 / 4.4

Buster (gen 1) 5.5

FLEXIFOIL

Sting 1.7 Punk

Rage 2.5 / 3.5/ 4.7

Revolution 1.5 SLE

17 ply Custom TRAMPA w/ verTIGo trucks

2 homebrew buggies,2 homebrew KYTBYKS,1 homebrew tandem trailer

GOPRO 3 WHITE, 3+ BLACK, HERO5 BLACK

CONTOUR HD

LET YOUR SOULFLY!

RIDER for KOKOPELLI KITER

|

|

|

WELDNGOD

Posts: 5143

Registered: 10-11-2006

Member Is Offline

Mood: Dyin' to go flyin'

|

|

here it is in 304 ,a lil cheaper http://www.onlinemetals.com/merchant.cfm?pid=22254&step=...

WELDNGOD on VIMEO

https://vimeo.com/user2580342

NAPKA US187

PKD

Combat 2.4 / 4.2

Century 1.8 / 5.5

Century II 2.2/2.8/3.5/4.5 /10.0

Brooza IV 3.0 prototype

Buster Soulfly 1.5 / 2.2 (KIA)/ 3.3 (lost at sea)

Buster Soulfly PRO 3.3 / 4.4

Buster (gen 1) 5.5

FLEXIFOIL

Sting 1.7 Punk

Rage 2.5 / 3.5/ 4.7

Revolution 1.5 SLE

17 ply Custom TRAMPA w/ verTIGo trucks

2 homebrew buggies,2 homebrew KYTBYKS,1 homebrew tandem trailer

GOPRO 3 WHITE, 3+ BLACK, HERO5 BLACK

CONTOUR HD

LET YOUR SOULFLY!

RIDER for KOKOPELLI KITER

|

|

|

John Holgate

Posts: 1512

Registered: 6-9-2009

Location: Australia

Member Is Offline

Mood: Cruising...

|

|

| Quote: |

The decision to make sub shafts like that is probably because it was a cheap solution.

|

No, it was the convenience of being able to use different width hubs and the convenience of using one nut to take tires on and off. The original Vmax

used the SS 20mm bolts with a lock nut on the inside - this required two spanners to be used at the same time to get the correct tension - which was

always a bit hit and miss. I have seen single bolt setups come loose and the wheel literally fell off. There's always more than one way to skin the

proverbial cat.

|

|

|

BeamerBob

Posts: 8308

Registered: 5-11-2007

Location: Down on the bayou

Member Is Offline

|

|

Yep. Not for cheap, but for security, convenience, and adaptability.

Coastal Wind Sports Team Rider

Landsegler Disc wheels

PTW Hero Buggy - XXtreme ApeXX Buggy US 88 - Libre Hardcore

IvanpahBuggyExpo.com

Youtube link

Bob Muse

HQ Montana X 8m, Montana IX 12m, HQ Ignition LEI 5m,

PL Phantom 12m, 15m, Big Blu 24m+, Synergy 10m, Venom 10m, 13m , Phantom II 12m Vapors 3.8, 5.4, Crosskite Sonic 7m, PKD Combat 10.3m

Uturn Butane 2.5m PKD Buster 3m Genetrix Hydra 7m Ozone Yakuza GT 14m

|

|

|

OffAxis

Posts: 202

Registered: 2-23-2016

Location: Central PA

Member Is Offline

|

|

How do you set your end play on the bearings with this method? Or do you just get it close and let the bearings walk. I guess you could stack

shims/spacers/washers and get it to tighten down to lock the inner races in place.

With a bolt method and proper spacers between the bearings, you can tighten down on the inner races and lock them into position. But then a Left Hand

threaded bolt should be considered for the rear right wheel.

Thoughts?

I have a feeling Flexifoil and PeterLynn concluded that using a bolt bearing spacer was the most economical choice while maintaining effectiveness.

I'm also going to assume during their testing, they have determined that a left hand threaded bolt is not required and using thread tape or lock tight

is sufficient to prevent the bolt coming loose.

|

|

|

hiaguy

Posts: 937

Registered: 6-26-2011

Location: Whitby, ON

Member Is Offline

Mood: Counting the days, and we're almost there

|

|

Quote: Originally posted by OffAxis  |

I have a feeling Flexifoil and PeterLynn concluded that using a bolt bearing spacer was the most economical choice while maintaining effectiveness.

I'm also going to assume during their testing, they have determined that a left hand threaded bolt is not required and using thread tape or lock tight

is sufficient to prevent the bolt coming loose. |

It's been interesting watching this thread progress.

I am about the least technical person on this board. I want to get in a basic buggy, and get down the beach, and back, with as little risk as

possible.

I have a stock PL XR+ and have never had an issue with the axel bolts (20mm) coming loose - no tape or loctite. Like you, I can only imagine that if

they're selling it that way, it's probably for a good reason (even if it is just plain old economics).

Now, I have had an issue with the stainless bolts on the side rails seizing, but then I learned about anti-seize, and life was good again.

I look forward to seeing your buggy - custom, stock, or otherwise - at WBB.

Go ahead... tell me to "go fly a kite!" Please!

Howard KC67 NAPKA District #12 Representative

Fly: A quiver of Lynx' and Cores (did someone say "Pansh"?), a couple o' Arcs, and a Rev to remind me about control

Ride: PL XR+

Where: 43.857899, -78.941661 and 38.970951, -74.828922

|

|

|

OffAxis

Posts: 202

Registered: 2-23-2016

Location: Central PA

Member Is Offline

|

|

I appreciate the kind words of encouragement. I hope that anyone who reads this thread can learn something or add their technical knowledge tips.

I'm looking forward to WBB this fall. Maybe if I get this build pulled together I'll have version 1 their and maiden it.

|

|

|

WELDNGOD

Posts: 5143

Registered: 10-11-2006

Member Is Offline

Mood: Dyin' to go flyin'

|

|

Quote: Originally posted by OffAxis  |

How do you set your end play on the bearings with this method? Or do you just get it close and let the bearings walk. I guess you could stack

shims/spacers/washers and get it to tighten down to lock the inner races in place.

With a bolt method and proper spacers between the bearings, you can tighten down on the inner races and lock them into position. But then a Left Hand

threaded bolt should be considered for the rear right wheel.

Thoughts?

I have a feeling Flexifoil and PeterLynn concluded that using a bolt bearing spacer was the most economical choice while maintaining effectiveness.

I'm also going to assume during their testing, they have determined that a left hand threaded bolt is not required and using thread tape or lock tight

is sufficient to prevent the bolt coming loose. |

You just cut it to size and use a washer with a nylock

nut, right hand on both is fine. In 10 yrs. I have only lost one wheel. A steel one like in your pic.... Weld cracked on the hub and the whole wheel

came off.Luckily it was the upwind rear so nothing bad happened.

WELDNGOD on VIMEO

https://vimeo.com/user2580342

NAPKA US187

PKD

Combat 2.4 / 4.2

Century 1.8 / 5.5

Century II 2.2/2.8/3.5/4.5 /10.0

Brooza IV 3.0 prototype

Buster Soulfly 1.5 / 2.2 (KIA)/ 3.3 (lost at sea)

Buster Soulfly PRO 3.3 / 4.4

Buster (gen 1) 5.5

FLEXIFOIL

Sting 1.7 Punk

Rage 2.5 / 3.5/ 4.7

Revolution 1.5 SLE

17 ply Custom TRAMPA w/ verTIGo trucks

2 homebrew buggies,2 homebrew KYTBYKS,1 homebrew tandem trailer

GOPRO 3 WHITE, 3+ BLACK, HERO5 BLACK

CONTOUR HD

LET YOUR SOULFLY!

RIDER for KOKOPELLI KITER

|

|

|

BeamerBob

Posts: 8308

Registered: 5-11-2007

Location: Down on the bayou

Member Is Offline

|

|

Yes the stub axle is much easier to get the correct pressure on the bearings because the jam nut already has the axle locked in place. Just tighten

the nylok to the tightness you want. Never had one come loose.

Coastal Wind Sports Team Rider

Landsegler Disc wheels

PTW Hero Buggy - XXtreme ApeXX Buggy US 88 - Libre Hardcore

IvanpahBuggyExpo.com

Youtube link

Bob Muse

HQ Montana X 8m, Montana IX 12m, HQ Ignition LEI 5m,

PL Phantom 12m, 15m, Big Blu 24m+, Synergy 10m, Venom 10m, 13m , Phantom II 12m Vapors 3.8, 5.4, Crosskite Sonic 7m, PKD Combat 10.3m

Uturn Butane 2.5m PKD Buster 3m Genetrix Hydra 7m Ozone Yakuza GT 14m

|

|

|

volock

Posts: 425

Registered: 8-5-2013

Location: Dallas, TX

Member Is Offline

Mood: Choosing your new depower foil quiver is hard...

|

|

In terms of wheels, I picked up fairly cheap from CL a set of motorcycle wheels (two actually). Total paid for both (one set of two front GSXR wheels

with tires, one set of two rear and one front steel spoked wheels) was around $120. Another $20 was spend on bearings/pipe to cut spacers for all the

wheels. Ironically the Spoked wheels came with 15mm bearings, but I needed 20mm (and they were old/rusted/groady), one GSXR wheel came in 21mm and one

in 23mm.

Fairly cheap overall for wheels that'll last me, and look good. The spoked ones still look a little rough, I'm slowly getting the steel wool to them

to get them looking shiny again. The others are gorgeous in my eyes. Nice and tall (and narrow enough) for back wheels for the grass fields with too

many divots/empty dirt lots so I don't bottom out like I occasionally did on my stock wheels. Weight is a bit higher than some would want, but I'm

not trying to freestyle with them anyway and don't have a very light buggy.

NAPKA US314 (Pi)

Stunt Kites: GoFlyAKite Parastunter 1.4m | Pacific Quest Mighty Bug 0.5m and 1.0m | Prism Flip Kite

Arcs: Peter Lynn Venom 19m

Depower Foils: Flysurfer Peak 12m, Peter Lynn Lynx (2015) 5m, 9m

FB Foils: HQ Beamer II 3.6m | Ozone LittleDevil 4.5m | Pansh Ace 5m, 7m | PKD Busta Soulfly 1.5m, 2.4m, Brooza II 7.5m | Prism Tensor 5m | Thunderwing

Parawings Set

LEIs: Cabrinha Convert SE 9m | Ocean Rodeo Prodigy 14.0m, Razor 12m, Storm 5.0m

Atomic Terrain Park Skis (w AT adapters for the wind dieing), Snowboard, 21" Isvidda Nordic Skates (NNN-BC and NIS bindings depending on the

pair),

Badfisher 11' SUP, Ocean Rodeo JT Pro 138cm

Landyachtz DH Race (Bear 852 Trucks), MBS Comp 95X

RB Swindler, Skorpion Skates

Sysmic S2 Dune Midi XL Buggy |

|

|

OffAxis

Posts: 202

Registered: 2-23-2016

Location: Central PA

Member Is Offline

|

|

What do must guys use for tires at Wildwood Beach Buggy? Barrow or Midi Tires?

What is preferred for riding in grass fields?

|

|

|

abkayak

Posts: 2271

Registered: 1-7-2012

Location: a.b. NY

Member Is Offline

Mood: loving life and becoming wise in simplicity

|

|

WW you will see every type tire being run... i wouldnt even say one over any other

the big bugs got big tires but plenty of barrows too

US-31...Cquad set/ 2.5 Bullet/ 2.6 Viper/ 2.9m Reactor/ 2- 3.5m Bullet/ 3.6 Beamer/ 4m Buster/ 4m Toxic/ 4m Ikon dp/ 4.5 Bullet/ 4.9m Blade/ 5.6

Twister/ 6.6m Blade/ 7.5 Apex/ 9m Fuel/ Phantom I 9,12,15,18/ 2 Flexibugs/ PL Big Foot/ landboards

|

|

|

hiaguy

Posts: 937

Registered: 6-26-2011

Location: Whitby, ON

Member Is Offline

Mood: Counting the days, and we're almost there

|

|

I ran barrows for couple of years, but the move to midis makes it a little easier when I get into the loose stuff at the top of the beach.

Go ahead... tell me to "go fly a kite!" Please!

Howard KC67 NAPKA District #12 Representative

Fly: A quiver of Lynx' and Cores (did someone say "Pansh"?), a couple o' Arcs, and a Rev to remind me about control

Ride: PL XR+

Where: 43.857899, -78.941661 and 38.970951, -74.828922

|

|

|

OffAxis

Posts: 202

Registered: 2-23-2016

Location: Central PA

Member Is Offline

|

|

Anyone familiar with buggy seat options. What are the options before I sign my mother up to making one for me(She has an upholstery sewing machine

and loves to sew)?

|

|

|

OffAxis

Posts: 202

Registered: 2-23-2016

Location: Central PA

Member Is Offline

|

|

Can anyone confirm that the spacer length is correct. I do not have a PL Rim to measure the distance between the inside of the bearings.

Both options, I think need some type of spacer or washer between the bolt or nut to not pinch the bearing seal. But it looks like the PL and Flexi

buggies don't have anything.

Option 1:

Option 2:

|

|

|

BeamerBob

Posts: 8308

Registered: 5-11-2007

Location: Down on the bayou

Member Is Offline

|

|

I don't think a washer is needed there.

If you weld the stub axle in, replacement will be difficult and could ruin a buggy outing or trip if the stub axle got bent.

If you use the bolt method, it would be better to also use a jam nut between the wheel and main axle.

Coastal Wind Sports Team Rider

Landsegler Disc wheels

PTW Hero Buggy - XXtreme ApeXX Buggy US 88 - Libre Hardcore

IvanpahBuggyExpo.com

Youtube link

Bob Muse

HQ Montana X 8m, Montana IX 12m, HQ Ignition LEI 5m,

PL Phantom 12m, 15m, Big Blu 24m+, Synergy 10m, Venom 10m, 13m , Phantom II 12m Vapors 3.8, 5.4, Crosskite Sonic 7m, PKD Combat 10.3m

Uturn Butane 2.5m PKD Buster 3m Genetrix Hydra 7m Ozone Yakuza GT 14m

|

|

|

OffAxis

Posts: 202

Registered: 2-23-2016

Location: Central PA

Member Is Offline

|

|

How often do 20mm bolts get bent? 20mm is a pretty hefty shaft to be bending especially at such a short distance. I would think that

there is a higher change of bending the axle tube where the seat rails connect.

Theoretically, according to the manufacture and my engineering training, the bearing requires some type of shim with a maximum diameter of 26mm to

prevent anything from clamping down on the seal. This applies to either case, bolt or stub shaft scenario illustrated above. I understand that you

can get away with out it but technically it's not the correct usage. Can anyone confirm that PL or Flexi does not use a shim?

I disagree with the jam nut being required in the illustration of the bolt example above. When the bolt is tightened it clamps the inner races,

spacer and axle insert together. If the spacer is the correct length, there will be no preload on the bearings allowing them to rotate freely. This

only works if the spacer is the correct length. The Bolt would be torqued to a proper torques spec provides enough elastic elongation of the bolt to

prevent it from coming loose. If the spacer is to short, the inner races will be squeezed together and pinch the ball bearings.

If I was to nitpick anything about the current PL and Flexi buggies, it would be the use of radial ball bearings. Due to all of the axial loading that

the kite puts on the bearings, the correct bearing to use would be an angular contact roller bearing, taper roller bearing, etc.

If I had these parts in my hand and could look at them to see if they will work, I would be able to answer some of these questions. But since I

haven't purchased anything yet, I have to go fishing is the sea of experience that the PKF contains.

|

|

|

WELDNGOD

Posts: 5143

Registered: 10-11-2006

Member Is Offline

Mood: Dyin' to go flyin'

|

|

You are waaaayyyyy overthinking this. Sideloading isn't an issue.If you get

pulled sideways too hard , you just sideslip a bit. And in10 yrs.,I haven't heard of a bearing causing a wheel to come off. You are waaaayyyyy overthinking this. Sideloading isn't an issue.If you get

pulled sideways too hard , you just sideslip a bit. And in10 yrs.,I haven't heard of a bearing causing a wheel to come off.

WELDNGOD on VIMEO

https://vimeo.com/user2580342

NAPKA US187

PKD

Combat 2.4 / 4.2

Century 1.8 / 5.5

Century II 2.2/2.8/3.5/4.5 /10.0

Brooza IV 3.0 prototype

Buster Soulfly 1.5 / 2.2 (KIA)/ 3.3 (lost at sea)

Buster Soulfly PRO 3.3 / 4.4

Buster (gen 1) 5.5

FLEXIFOIL

Sting 1.7 Punk

Rage 2.5 / 3.5/ 4.7

Revolution 1.5 SLE

17 ply Custom TRAMPA w/ verTIGo trucks

2 homebrew buggies,2 homebrew KYTBYKS,1 homebrew tandem trailer

GOPRO 3 WHITE, 3+ BLACK, HERO5 BLACK

CONTOUR HD

LET YOUR SOULFLY!

RIDER for KOKOPELLI KITER

|

|

|

| Pages:

1

2

3

4 |